Ultrasonic drilling/welding/knives/scalpels/scalarsĪpplications for operation well below resonance include:.Piezo actuator applications for operation at or near resonance include: Multiple piezos can be used to provide a stronger haptic response and more localized haptic feedback. They can be made into custom shapes for specific applications or packaging constraints, and are offered as single-layer or multilayer structures. Piezos are available in many different shapes, sizes, thicknesses, voltage ranges, force, and capacitance ratings. Piezo-based haptics offer several advantages including a fast response time, thin profile, low power, and a wide range of available piezo characteristics and mounting techniques.

One of the more promising approaches for real-time tactile feedback uses piezoelectric actuation, which has been available in a small number of consumer devices for several years. Recently, the lack of good tactile feedback has fueled the demand for adding electrically-based tactile feedback systems.įigure 1. Users are familiar with the "push to activate" feel of mechanical feedback to indicate a successful entry, for instance, on a keypad (Figure 1).

#ULTRA SONIC PIEZO ACTUATOR PORTABLE#

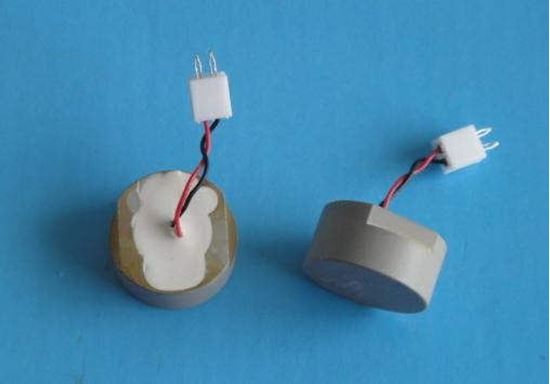

With the advent of touch screens replacing mechanical buttons on portable handheld consumer devices, the loss of tactile feedback has created a need for real-time feedback. This article explains the basics of piezoelectric-based actuation and how it offers a fast response time, thin profile, and low power, all of which are important in handheld applications.Ī version of this app note was published by Planet Analog in two parts, part 1 appeared on Novemand part 2 appeared on November 22, 2010. Several haptic technologies are available now, including but not limited to vibration motor actuation, piezoelectric actuation, and electro-active polymer actuation. It provides a sense of touch in a user-interface design and is the newest major interface on smartphones and other portable consumer-electronic devices. There are a large variety of different designs optimized for different applications, from extremely high force or microsecond response, to long travel ranges in the millimeter and centimeter range.Implementing tactile (haptic) feedback in consumer-electronic devices enhances the user's experience.

Not all piezo actuators and motors are created equal. Piezo University: Designing with Piezo Mechanicsĭifferent Types of Piezo Mechanisms Solve Different Problems Piezoelectric Products for Motion Control: PI also provides value added manufacturing and custom assembly of piezoelectric components for OEMs. in Semiconductors Bio Tech & Mecial Engineering Lasers, Optics, Microscopy Aerospace Engineering Precision Machining Astronomy and Microsystems Technology. PI and PI Ceramic are the leading manufacturers of piezoelectric mechatronic systems such as piezoelectric actuators, pzt transducers for motion control, nano positioning and industrial applications, e.g. Piezoelectric Transducers can also be used for sensing, ultrasound generation and medical applications. Piezoelectric mechanisms can provide very fast and precise motion. Piezo Mechanisms, Piezoelectric Transducers, Piezo MechanicsĮngineered for Motion, Sensing and Dispensing

0 kommentar(er)

0 kommentar(er)